Boost Your Brand with Our Custom Foil lids Solutions

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus,

luctus nec ullamcorper mattis, pulvinar dapibus leo.

Converting Ideas Into Real Lids

From ideas to real lids, Tilda brings your vision to life. Whether you are in need of a specific shape, size, or branding element, we’re here to convert your ideas into real die-cut aluminum foil lids.

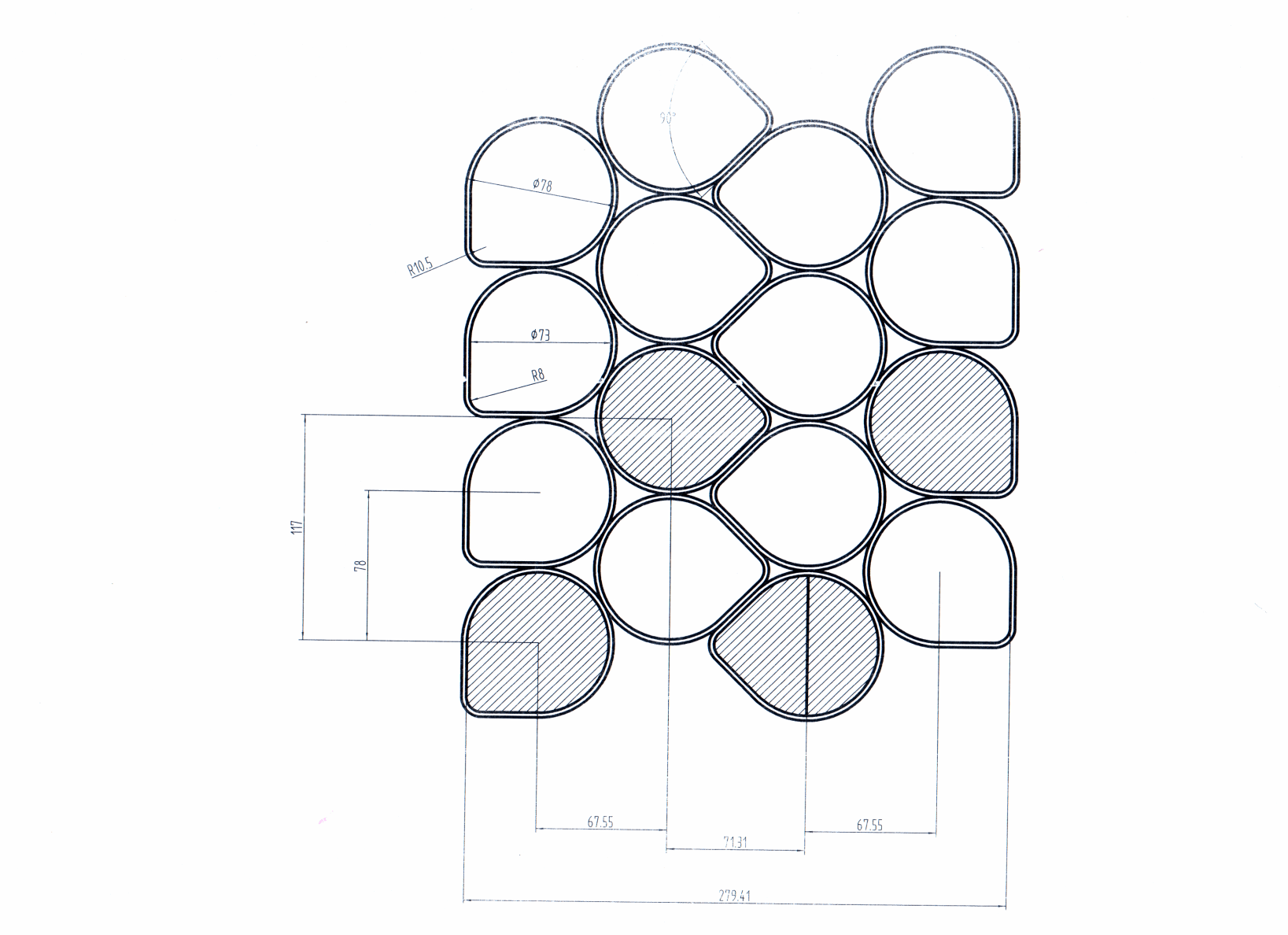

73 mm Aluminum Lids with a "V" Lip

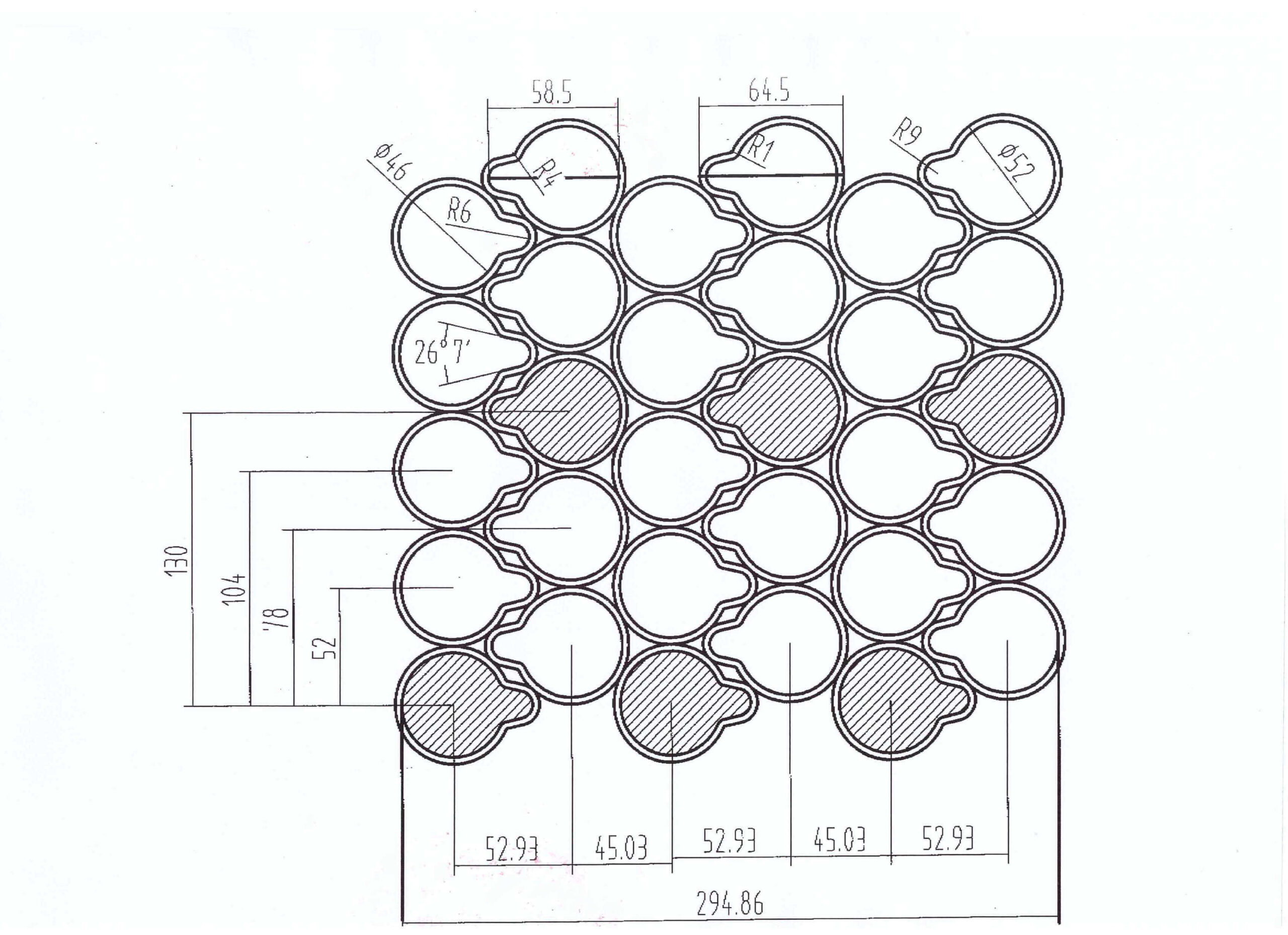

46 mm Heat Seal Foil Lids with a "U" tab

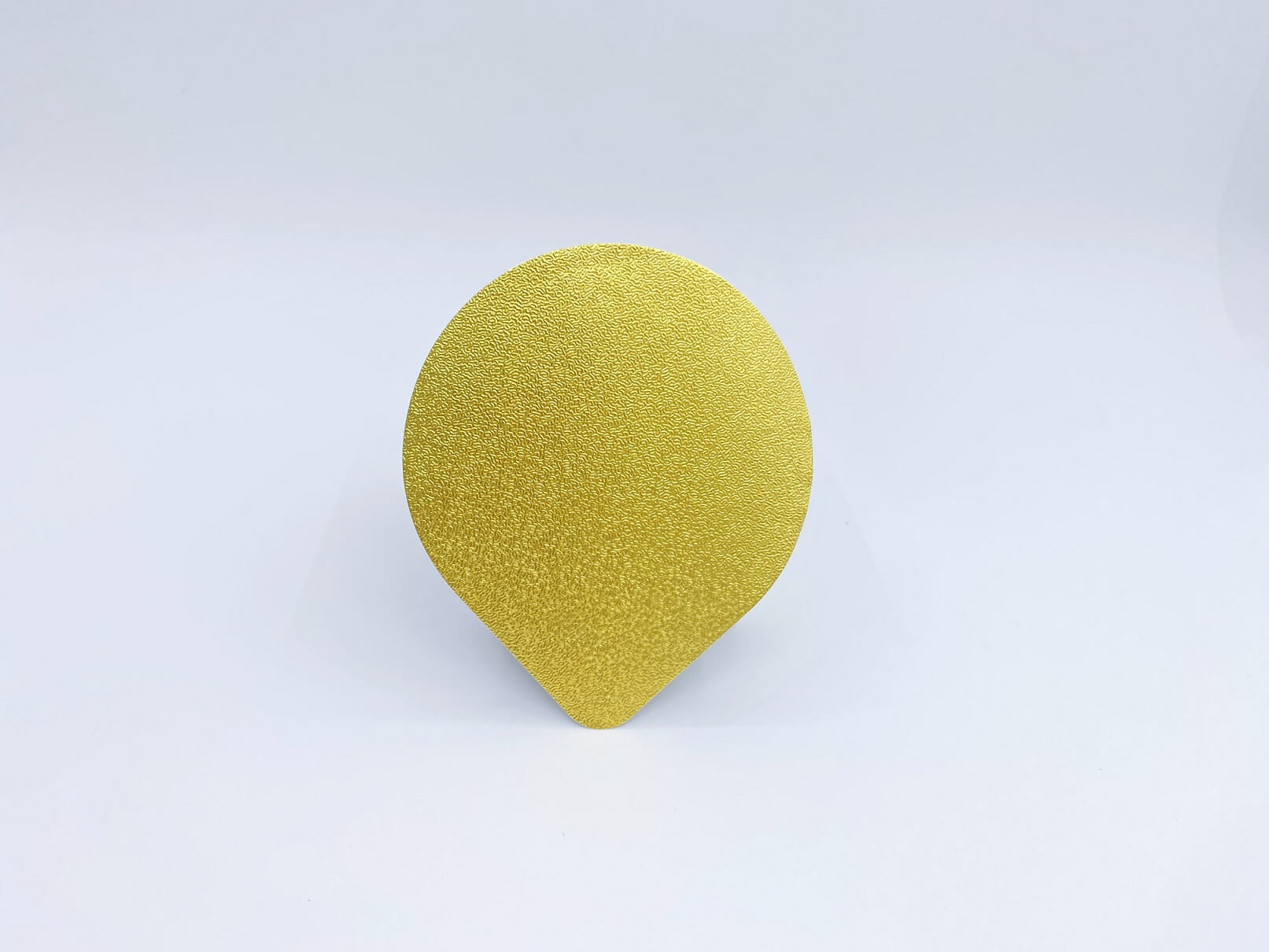

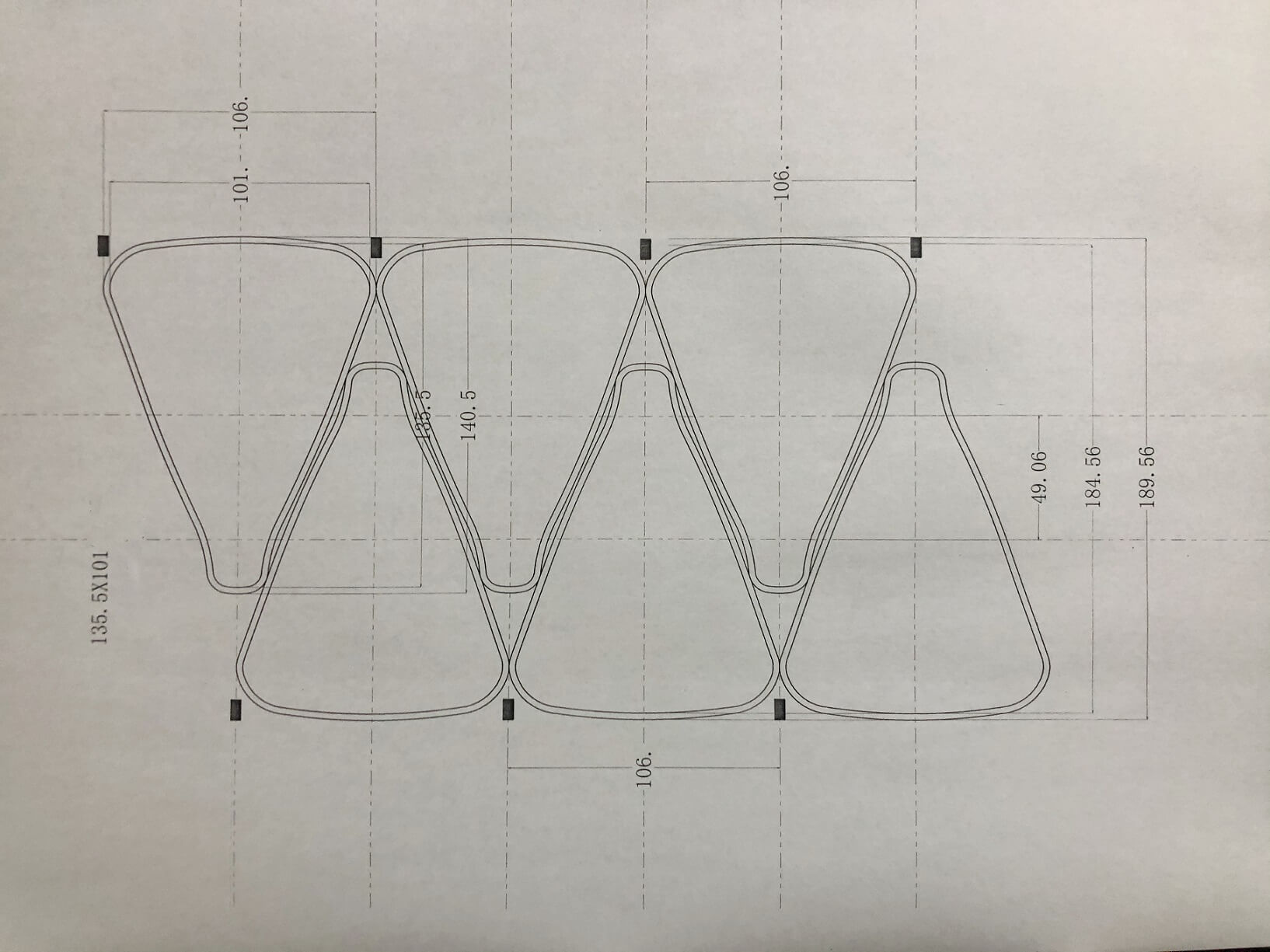

Die -Cut Lids with Triangle Shape

Foil Lids Customization Journey

We have a team of experienced creatives ready to assist you at every stage of the printing process, providing valuable insights for your product packaging. Whether you’re working with a new design or existing artwork, our team will convert your files and apply pre-press preparations to ensure they are fully ready for printing.

Design & Development

Clients provide artwork root file(Adobe Illustrator format preferred) or physical samples

Design & Development

Providing or designing artwork proofs for clients’ approval purpose for free.

Design & Development

Clients approve artwork proofs or put up the revision suggestions

Design & Development

Offering artwork proofs supposed to be revised to clients for final approval

Prototyping

Start to make printing plates after getting clients approval of revised artwork

Prototyping

Start a trial printing for approval on the production line after getting the plates

Validation

Clients approval the trial printing samples on site or by sending physical samples

Mass Production

Get started to proceed with mass production after approval of samples

Featured Aluminium Lids & Markets Served

Tilda provides die-cut lidding foil for a range of markets, including dairy, food, dips and condiments, beverages, and gelatin products. We prioritize the production of high-quality die-cut lidding in various shapes, sizes, and finishes.

Visit Us

Seamless Production Journey of Aluminum Foil Lids

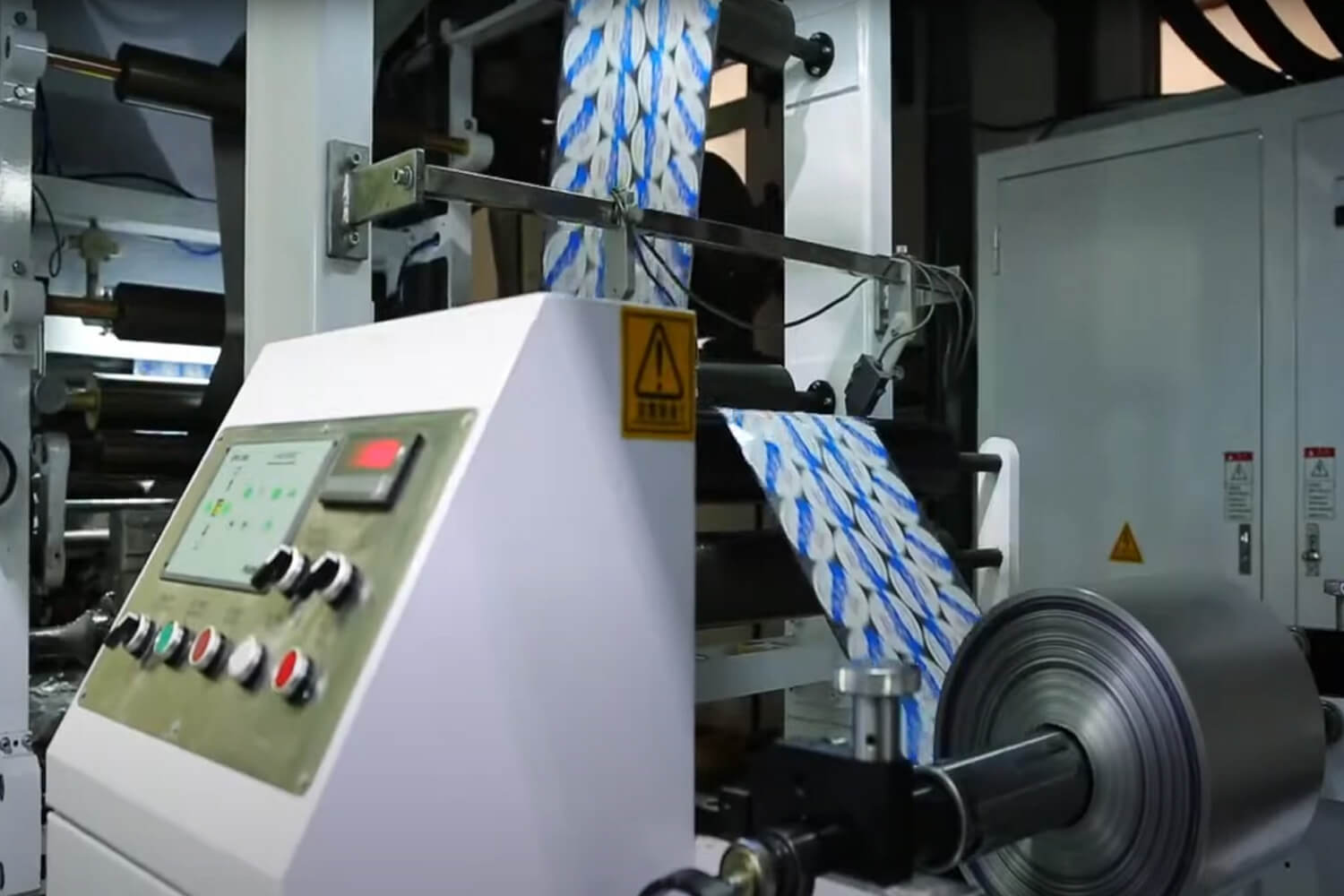

With advanced production capabilities, we guarantee timely fulfillment of your lidding foil orders. Our facility is equipped with 2 computer-controlled high-speed gravure printing machines, 2 dry lamination machines, a 150-square-meter curing workshop, and 10 die-cutting machines, enabling us to meet large-scale demands efficiently.

Raw Material Aluminum Foil Selection

8-Color High-Speed Gravure Print Machine

High-Speed Dry Type Laminating Machine

Curing Room for Solidification

Multiple Sets of Die-Cutting Machine

Aluminum Foil Lids Laboratory Detection

Lids Foil Quality Control

Lids Weighing

Packaging Lids Into Boxes

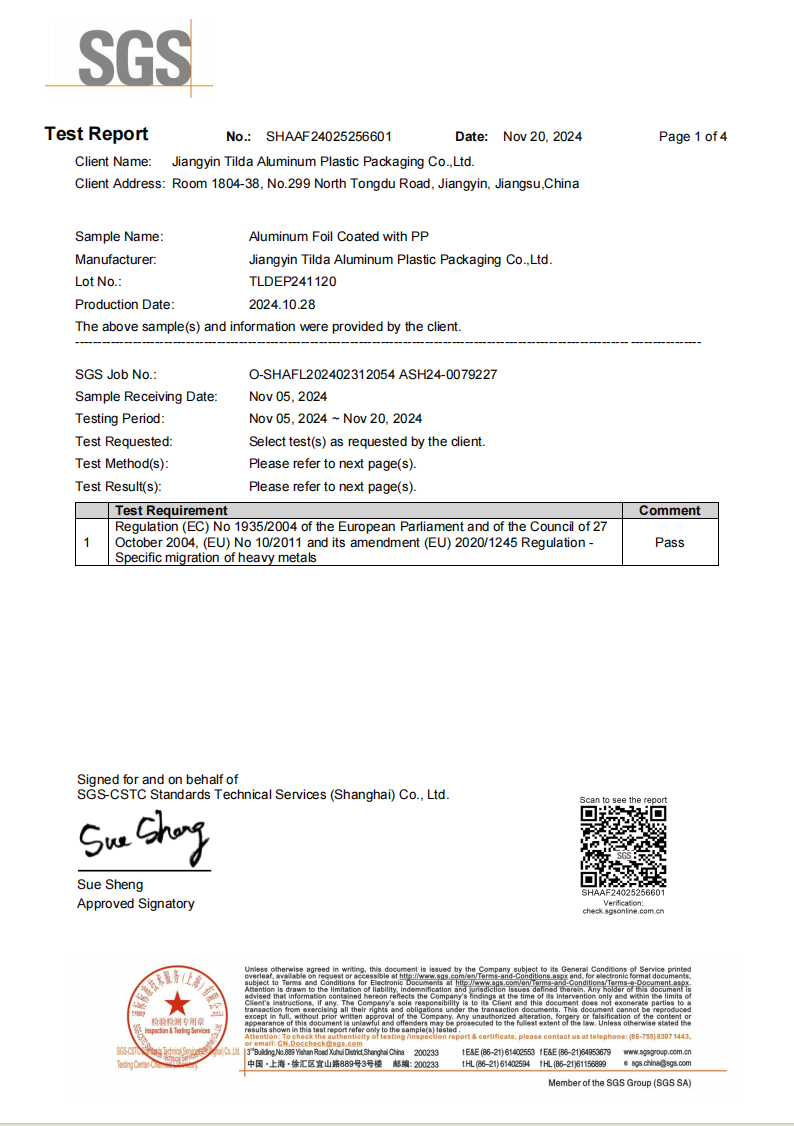

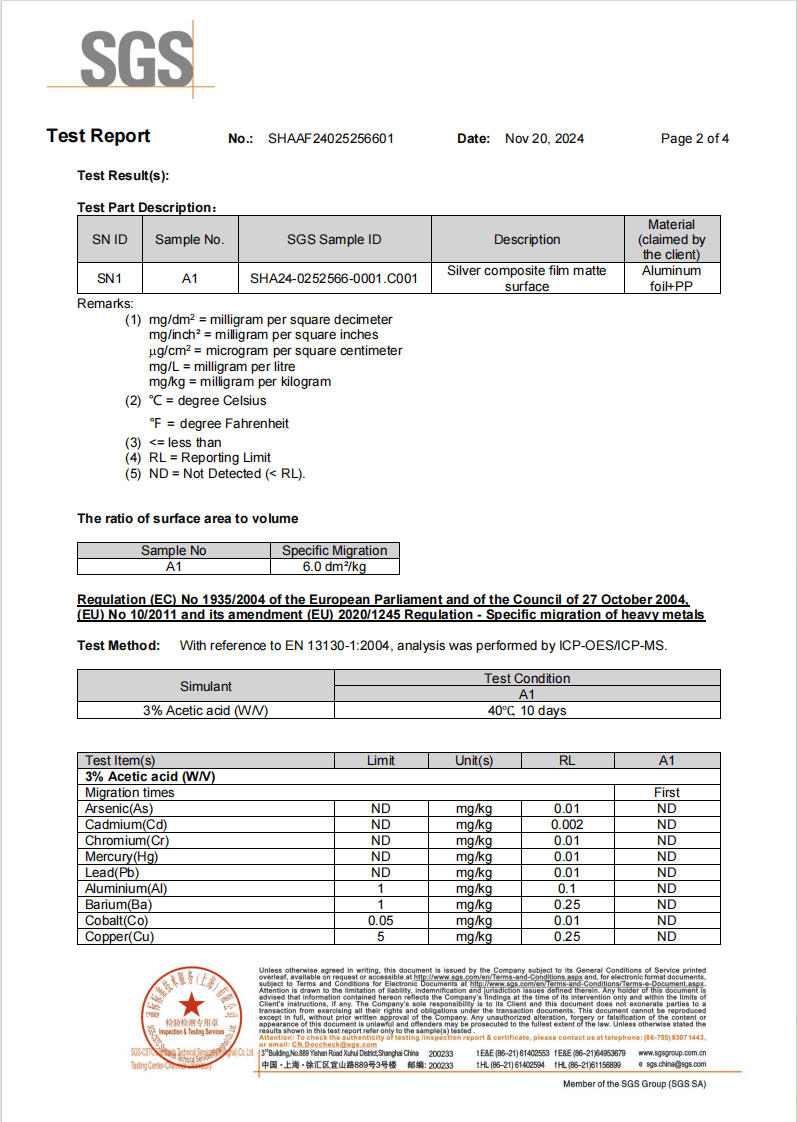

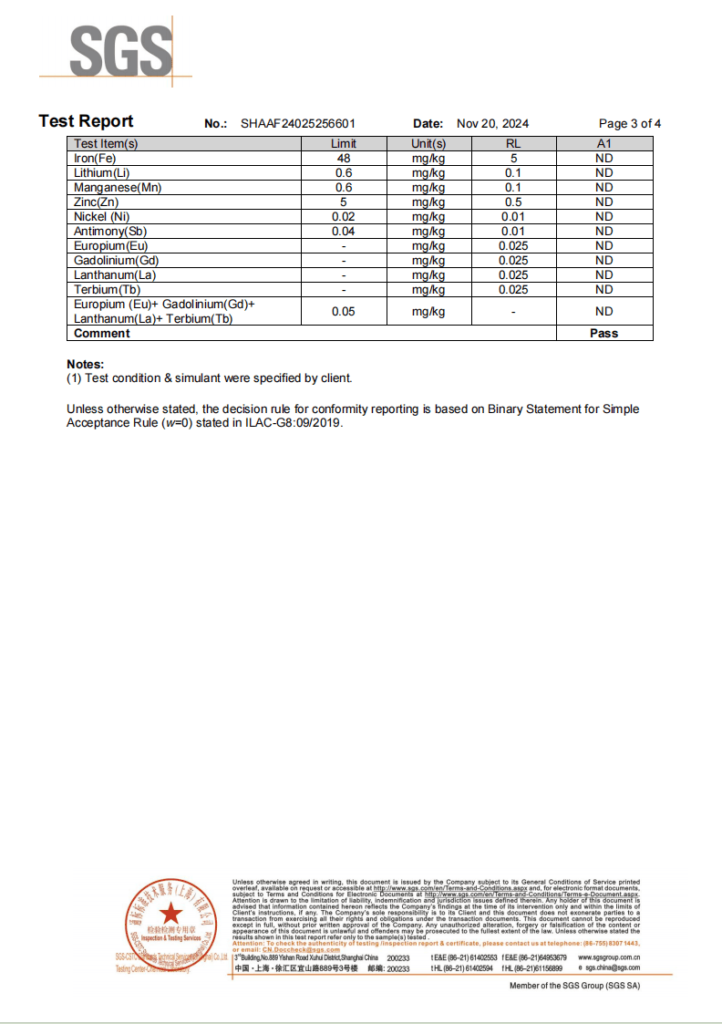

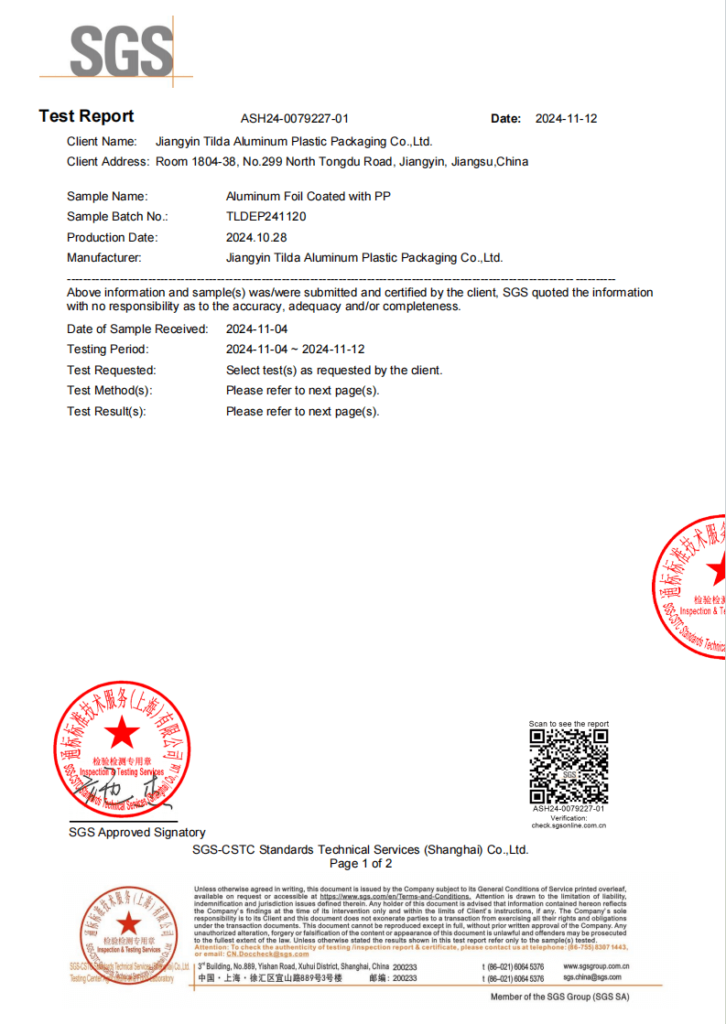

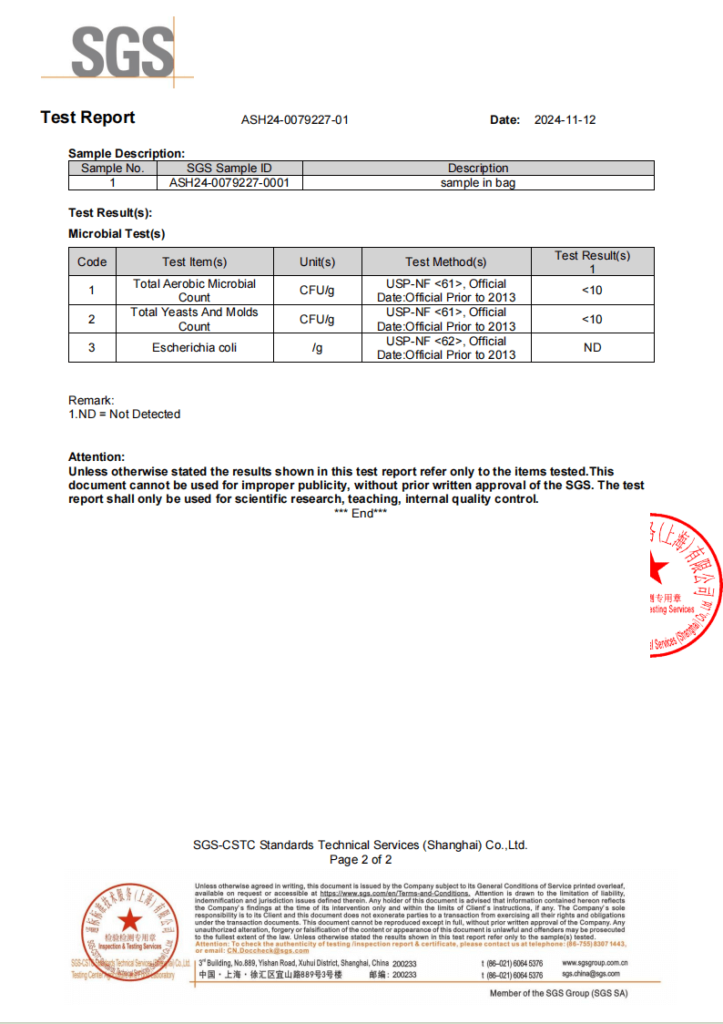

Certifications

Frequently Asked Questions

Tilda has been involved in aluminum foil lids industry for years. Throughout this time, we have encountered various questions, here are the most common concerns our customers have before starting a business with us.

Die-cut foil lid refers to pre-cut individual lids that are used to seal packaged goods in cups and other containers. It is converted from aluminum rolls to individual foil lids in precise shapes to fit different container styles. Die-cut lids can be printed or unprinted.

Yes, we focus on food safety and health from the very beginning. We collaborate only with reputable suppliers who can provide the third-party testing reports compliant with Relevant laws and regulations standards.

Our aluminium foil lids are primarily heat-sealable.

You’ll require a heat-sealing machine, which could be manual, semi-automatic, or fully automatic.

Typically, we suggest a heat-sealing temperature of 180-220°C, a pressure of around 0.6Mpa, and a sealing time of approximately 0.5~1.2 seconds.

Certainly, we offer free plain samples or the samples we currently have for your evaluation. For custom-printed samples, plate-making and sampling fees apply but the sampling fees shall be refunded in your future orders.

Our standard MOQ is 100,000 pieces per size. However, we are open to be flexibility.

Generally, production is completed within 20 straight days, but this can vary depending on the order quantity.

Yes, we offer customization.

To save your time, The ideal file types include AI, PSD, EPS, and CDR.Please note that we may make necessary adjustments to your original artwork to align it with our production capabilities.

Our fully automated production lines can accommodate up to 8-color printing.

Generally, the plate-making fee is one-time for a specific design that you intend to use for an extended period. Reorders using the same design will not incur additional plates fees. If the design changes, a new plate-making fee will be charged.

We recommend storing them at room temperature in their original packaging, away from direct sunlight and heat.

Stored in their original packaging at room temperature, our foil lids have a shelf-life of 12 months from the date of manufacturing.

Get Free Samples and Artwork Proofs

Reach Out Now to discuss how we can elevate your operations to the next level. Let’s embark on a journey towards sustainable profitability, together.